D Center Latch Drill Collar Elevator

1.Description

⑴DD center latch drill collar elevators are convention square center door elevators to handle pipes in oil and gas drilling operation.

⑵DD center door square drill collar elevators made from high quality alloy steel with both advanced technology and heat treatment. The center latch square drill pipe elevators are verified by strength test and NDT referred to ANSI/ASTM A487. center latch square drill pipe elevators can handle taper shoulder drill pipe from 2½in to 11in O.D. .at the temperature minus 20℃. The rating loads are as follows: 1350kN, 2250kN.

⑶The sizes of contact surface between elevator and elevator link or between elevator and pipes conform to the specifications of Principal Contact Surface Size for Hoisting Equipment in SY/T 5288 and API Spec 8C.

⑷DD center latch square drill collar elevators have been strictly Volumetric Radiographic Tested and Surface NDE and Verification tested and Ex-work tested, every technical parameters and properties of the equipment offered to customers are in accordance with the specifications of API Spec 8C and SY/T 5035 Elevator link, Elevator and Manual Tong.

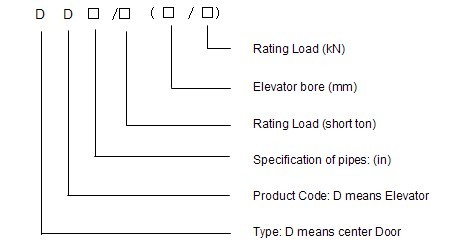

⑸The compositions and their representing meanings of DD center latch square drill collar elevators :

2.Structural

Type DD center latch square drill collar elevators are center door elevators, they consist of two main bodies, latch, pins, shield and etc. The two main bodies (right body and left body) are jointed by the hinge pin; the latch is fitted to left main body and can be rotated around it. The latch is equipped with spring with which the latch can be back to its original position. The shield is fitted to latch and can be recovered to the position paralleled to latch with the force of spring. When close the elevator, the shield can enter into the bock of the right body to lock itself. When open the elevator, pull shield and the shield can be discharged from the block in right body, and pull on, the latch can be discharged from right body, and then the elevator is opened. When close the elevator, only to pull the two handles of the elevator toward each other until the latch and shield return to the close position with the force of spring, the elevator is closed. To avoid injure, the elevator is equipped link block.

3.Specifications for center latch square drill collar elevator

Chart for specifications of DD certer latch square drill collar elevators:

⑴With lifting groove spiral drill collar:

| Specification | Elevator bore O.D. (mm) |

Elevators recess

O.D.(mm) |

Rating Load kN/t |

Elevators tag | |

| top bore | bottom bore | ||||

| DD5¼/150 | 123.83 | 136.53 | 120.65 | 1350 (150) |

DD5¼/150SR1 API 8C SPL1 |

| DD5½/150 | 130.18 | 142.88 | 127.00 | DD5½/150SR1 API 8C SPL1 | |

| DD5¾/150 | 113.35 | 149.23 | 130.17 | DD5¾/150SR1 API 8C SPL1 | |

| DD6/150 | 139.70 | 155.58 | 136.53 | DD6/150SR1 API 8C SPL1 | |

| DD6¼/150 | 146.05 | 161.93 | 142.88 | DD6¼/150SR1 API 8C SPL1 | |

| DD6½/150 | 152.40 | 168.28 | 149.23 | DD6½/150SR1 API 8C SPL1 | |

| DD6¾/150 | 157.16 | 174.63 | 152.40 | DD6¾/150SR1 API 8C SPL1 | |

| DD7/150 | 163.51 | 180.98 | 158.75 | DD7/150SR1 API 8C SPL1 | |

| DD7¼/150 | 169.86 | 187.33 | 165.10 | DD7¼/150SR1 API 8C SPL1 | |

| DD7½/150 | 176.21 | 193.68 | 171.45 | DD7½/150SR1 API 8C SPL1 | |

| DD7¾/150 | 182.56 | 200.03 | 177.80 | DD7¾/150SR1 API 8C SPL1 | |

| DD8/150 | 188.91 | 203.38 | 184.15 | DD8/150SR1 API 8C SPL1 | |

| DD8¼/150 | 195.26 | 212.73 | 190.50 | DD8¼/150SR1 API 8C SPL1 | |

| DD9/150 | 212.73 | 231.78 | 196.85 | DD9/150SR1 API 8C SPL1 | |

| DD9½/150 | 225.43 | 244.48 | 219.08 | DD9½/150SR1 API 8C SPL1 | |

| DD9¾/150 | 231.78 | 250.83 | 225.40 | DD9¾/150SR1 API 8C SPL1 | |

| DD10/150 | 238.13 | 257.18 | 231.78 | DD10/150SR1 API 8C SPL1 | |

| DD11/150 | 263.58 | 282.58 | 257.18 | DD11/150SR1 API 8C SPL1 | |

⑵With lifting groove spiral drill collar:

| O.D. | Bore Code | Top Bore | Bevel | Bottom Bore |

| 2½in | 201 | 2-21/32in | 1/16in | 2-21/32in |

| 2¾in | 203 | 2-29/32in | 1/16in | 2-29/32in |

| 3in | 205 | 3-5/32in | 1/16in | 3-5/32in |

| 3⅛in | 206 | 3-9/32in | 1/16in | 3-9/32in |

| 3¼in | 207 | 3-13/32in | 1/16in | 3-13/32in |

| 3½in | 209 | 3-21/32in | 1/16in | 3-21/32in |

| 3¾in | 211 | 3-29/32in | 1/16in | 3-29/32in |

| 4in | 213 | 4-5/32in | 1/16in | 4-5/32in |

| 4⅛in | 519 | 4-9/32in | 1/16in | 4-9/32in |

| 4¼in | 548 | 4-13/32in | 1/16in | 4-13/32in |

| 4½in | 215 | 4-21/32in | 1/16in | 4-21/32in |

| 4¾in | 354 | 4-15/16in | 1/16in | 4-15/16in |

| 5in | 552 | 5-3/16in | 1/16in | 5-3/16in |

| 5¼in | 219 | 5-7/16in | 1/16in | 5-7/16in |

| 5½in | 411 | 5-11/16in | 1/16in | 5-11/16in |

| 5¾in | 222 | 5-21/32in | 1/16in | 5- 21/32in |

| 6in | 349 | 6-7/32in | 1/16in | 6-7/32in |

| 6¼in | 348 | 6-15/32in | 1/16in | 6-15/32in |

| 6⅜in | 331 | 6-19/32in | 1/16in | 6-19/32in |

| 6½in | 135 | 6-23/32in | 1/16in | 6 23/32in |

| 6¾in | 338 | 7in | 1/16in | 7in |

| 7in | 372 | 7¼in | 1/16in | 7¼in |

| 7¼in | 335 | 7½in | 1/16in | 7½in |

| 7½in | 137 | 7¾in | 1/16in | 7¾in |

| 7¾in | 550 | 8in | 1/16in | 8in |

| 8in | 334 | 8¼in | 1/16in | 8¼in |

| 8¼in | 347 | 8½in | 1/16in | 8½in |

| 8½in | 580 | 8-25/32in | 1/16in | 8-25/32in |

| 8¾in | 226 | 9-1/32in | 1/16in | 9-1/32in |

| 9in | 356 | 9-9/32in | 1/16in | 9-9/32in |

| 9¼in | 227 | 9-17/32in | 1/16in | 9-17/32in |

| 9½in | 346 | 9-25/32in | 1/16in | 9-25/32in |

| 10in | 228 | 10-11/32in | 1/16in | 10-11/32in |

| 10½in | 229 | 10-27/32in | 1/16in | 10-27/32in |

| 11in | 230 | 11-11/32in | 1/16in | 11-11/32in |